Custom Component Manufacture

We offer a custom component drawing and manufacture service making single pieces and also larger volumes. These components can be as simple as flat sheet separator to the more complexed gripper end milled clamps, which are the examples shown.

The manufacture of these components can be done through either the supply of a sample or through detailed engineering drawings. To offer the best service possible send us your component sample and we will do the rest. All our components are managed and signed off by our highly qualified and experienced in house Chartered Engineer.

To show the differences in components please see the examples below that have been produced recently by our team.

One off Milled End Clamp

This picture shows a gripper end clamp which was manufactured for a Hashimoto printing press. This single cast block, which would have been milled from a single piece of material. When the sample was received it had been dropped and had smashed into multiple pieces. As you can see by the photo we reassembled the pieces (right) and then milled the new item (left) will identical holes and tapped a new grub screw. This was reproduced in 4 working days returning the machine back to work. This type of work had to be assessed by the hour due to its complexity and is the most expensive thing to reproduce.

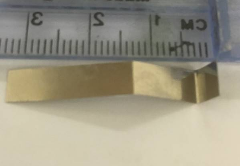

Multiple Machine Gripper Components

This picture shows a component made through automated methods in higher volumes and as a result was a much lower price. This gripper component was made by receiving a single sample, which was created electronically, then laser cut and pressed to shape. This then was stippled on the end to give a great gripper texture to hold the papers as they go through the press. One of the most important aspects when recreating this item is the large holes alignment to allow the item to fit seamlessly onto their support shaft.